AirPower Europe GmbH

Supplier of AirPower Europe GmbH actuators

aim fluid control is the supplier of the actuators of AirPower Europe GmbH. They are a premium supplier of industrial valves for the entire process technology. AirPower Europe GmbH has over 35 years of experience in industrial process valves, automation and technology and is located in Dattenberg, near Linz on the Rhine, between Bonn and Koblenz

Everything from one source

The automation specialists at AirPower Europe GmbH supply industrial actuators in the most commonly used material combinations and nominal widths for the requirements of Industry 4.0. All from one source and under one roof.

Quality & absolute reliability

All actuators are dimensioned in their own factory and professionally with actuators as assemblies. Exceptional quality standards, absolute reliability and an optimal price-quality ratio make AirPower Europe GmbH a strong and special partner.

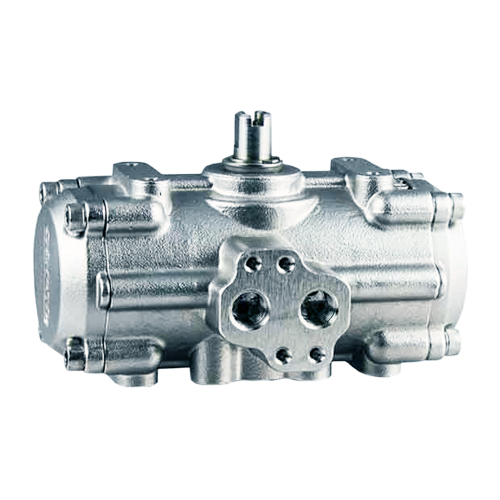

Twintorque® actuator

AirPower Europe GmbH is proud to present the new quarter turn actuator twin-torque©. This is a new concept in the field of drives. Get more results with the innovative actuators from AirPower Europe GmbH: a technical and high-quality product, designed and produced according to international standards. These values guarantee absolute quality at all times. We are happy to inform you about the advantages and applications of the twintorque® actuator. Call or email aim fluid control and we will provide you with the necessary information.

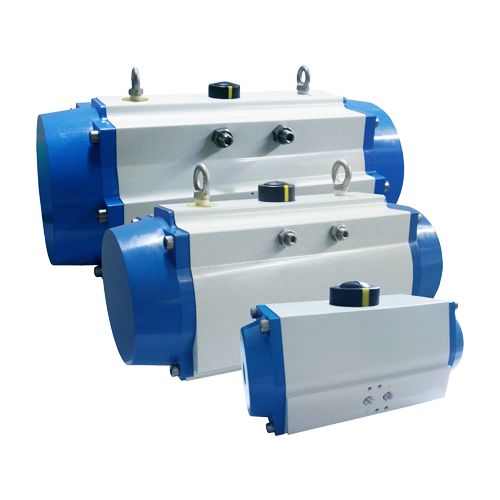

AirPower | Pneumatic Actuator

AirPower | Pneumatic Actuator

AirPower | 3-positions Actuator

AirPower | Stainless steel Pneumatic Actuator

AirPower Europe GmbH | Double acting pneumatic actuators

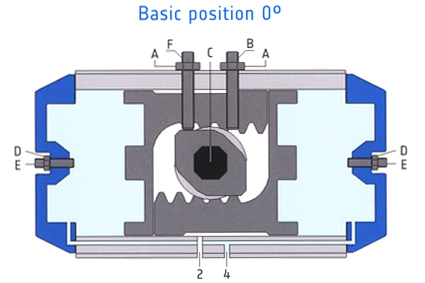

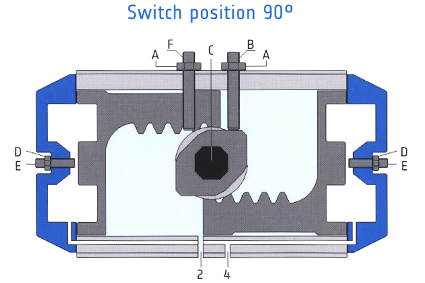

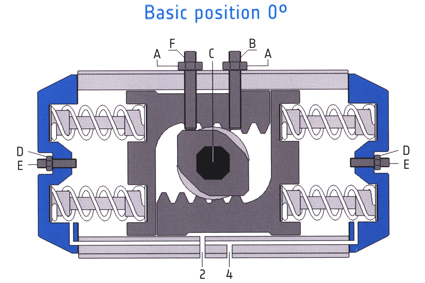

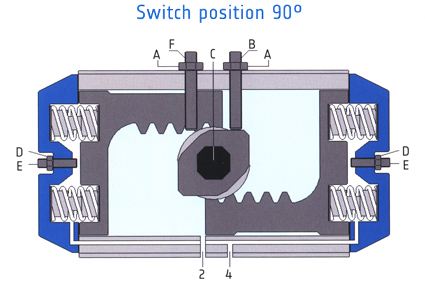

The pneumatic actuators from AirPower EuropeGmbH are visualized in the images below. On the basis of these illustrations we explain how these actuators work. When pressure is exerted on opening "2", both pistons move from their basic position of 0° and move to 90 ° switching position. The power of the pistons is then transferred to pinion "C" via the rack. If the pistons get pressure through opening "4", then both pistons move back together to basic position 0 °.

AirPower | Start position 0°

AirPower | Switched position 90°

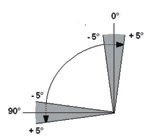

AirPower | End position setting

AirPower | End position setting

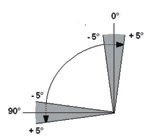

In a pressureless state, the angular displacement of both end positions can be adjusted by the set screws "B" and "F" between + 5 ° and -5 °

The lock nuts A ensure that the new position can be secured.

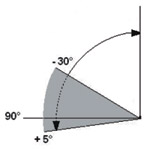

AirPower | Stroke limit

AirPower | Stroke limit

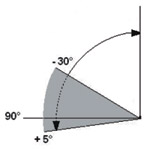

In a pressureless state, the nominal rotation angle in the switched position can be adjusted with the set screws "E" between + 5 ° and -30 °.

The lock nuts "D" ensure that the new position can be secured.

AirPower Europe GmbH | Single-acting pneumatic actuators

airpower has released two different pneumatic actuators: single-acting and double-acting actuators. When the pressure is exerted on opening "2", both pistons move against the spring pressure from the 0 ° basic position to the 90 ° switching position. When the pressure in the inner chamber escapes through opening "2", the springs push the pistons back to the basic position of 0°. The number of springs, often 4 to 12, must be adjusted in advance to the control pressure and the desired torque.

AirPower | Start position 0°

AirPower | Switched position 90 °

AirPower | End position settings

AirPower | End position settings

In a pressureless state, the angular rotation of both end positions can be adjusted by the set screws "B" and "F" between + 5 ° and -5 °. The lock nuts "A" ensure that the new position can be secured.

AirPower | Stroke limit settings

AirPower | Stroke limit settings

With stroke limitation, the non-pressurized state can be adjusted to the nominal rotation angle in the switched position with the set screws "E" between + 5 ° and -3 ° o. The types APD / APS-050-210 have a stroke limit adjustment in one direction as standard. This means that they can open or close. The "D" lock nuts ensure that the new position can be insured. The end position and stroke limit are the same for both single-acting and double-acting airpower actuators.

The advantages of the AirPower actuator

The AirPower actuator has several advantages. For example, the single-acting and double-acting actuators have the same dimensions, with a swivel angle of 90° to 180°. The rotation angle of both actuators is adjustable from 180° to 120°. But there's more:

Construction features

The same size for the double and single-acting actuators with a swivel angle of 90 °. 180 ° rotation angle adjustable from 180 ° to 120 °.

- Low inventory costs because only double-acting actuators must be kept in stock and single-acting actuators can be made by simply installing the springs.

- Simple, safe operation through the use of enclosed, pre-tensioned springs.

- Covers a very wide range of applications.

Position indicator

The position indicator is mounted on the actuator in such a way that it does not interfere with the NAMUR interface, according to VDI / VDE 3847.

- Use of cost-efficient standardized components.

- Faster, less expensive assembly of signal units.

- Indicators can be seen from long distances.

End positioning

Approximately two independently functioning settings can be adjusted individually in a range of + 5 ° to -5 ° on the APD / APS-040-350 screw types.

- Butterfly valves: discs only need to touch the seal and the valve is closed. - Longer service life due to low wear. Low torque and low cost choice of actuator.

- Ball and shut-off valves: open position of the ball, i.e. the plug can be precisely adjusted.

- Avoids turbulent flow of the medium and cavitation.

Stroke limiter

In addition to the final position of the twintorque°, the APD / APS-050-210 types have a stroke limit adjustment in one direction (open or close) as standard. This means that the nominal rotation angle can be adjusted within a range of + 5 ° or -30 °

- The additional limitation of the stroke means that the amount of flow can be reproducibly adjusted for butterfly valves and valves.

- Cost savings, since a special solution is not required (eg special switch cams or electrical solutions)

Corrosion protection: housing and caps

Aluminum housing is hard anodized and also powder coated from the outside. Caps in die-cast aluminum are also powder coated. Caps in die-cast pistons is likewise powder-coated

- Deployment possibilities in almost all situations, especially in critical environments

Corrosion protection: piston

Aluminum die-cast pistons are hard anodised.

- Functional protection, even with the use of critical control devices.

Corrosion protection: air force safety springs

Enclosed springs are covered with plastic.

- Good corrosion protection ensures a good service life.

- Made from APS-070 non-ferrous metal.

- Lower service and maintenance costs. - No risk of accidents.

O-rings and bearings

Standard seals can be used from -35 ° to + 80 ° C.

- Large temperature range. - Cost effective maintenance through simple exchange of valves and wearing parts.

ISO flange patterns

Multiple ISO flange patterns per actuator size.

- Cost savings through flexible automation of valves

Silicone free

Aluminum die-cast pistons are hard anodised.

- Use also in locations where silicone is not allowed, e.g. in paint sprayers.

Download sheets

Download Datasheets AGD AGS

Download Datasheets AGD AGS APD APS

Download Datasheets APD APS

Tailor-made solutions

Based on the trinity of People, Customization & Technology, relieving you is the core of what aim fluid control has to offer you. If technology is second nature to us, relieving you might be our first. We call it relieving you because we offer technical, logistical and cost-saving solutions - from idea to solution & implementation - so that the continuity of your flow & fluid process remains guaranteed and / or is improved as well as your peace of mind.

Advice & Deed

From advice on complex issues to the simple ordering of (repeat) orders via our webshop, you can deploy us as a supplier of parts, assembler, product specialist, process specialist, technical adviser, engineer, product developer, project manager or total provider, depending on your needs.

The right technical, logistical and customized solutions

Solving your issues is central at all times. This concerns more than just the focus on applications, processes and products. Our multiple brand policy gives you a wide choice of products and price categories. In combination with our technical know-how and solution-oriented approach, we can deliver customized solutions in many, if not all, cases.

Call or e-mail us!

We will of course be happy to advise you on your technical and logistical support and all your customized work. Do you want to know more or do you have questions?

Then please contact us. This can be done by calling +31(0)499 49 10 90. Feel free to schedule an appointment with us by filling in the contact form.

Ekkersrijt 7310

5692 HH Son en Breugel

+31(0)499 49 10 90

info@aimfluid.nl

Stay informed of news & promotions