All types of Solenoid Valves

So many Applications, so many Solenoid Valves.

aim fluid control offers you an extensive range of solenoid valves for the most diverse applications

Read more about solenoid valves on this page. Do you have questions? Call or email us.

Solenoid valve overview page

- What does a solenoid valve do?

- The 4 different types of solenoid valves?

- What are the benefits of a solenoid valve?

- How do you select the right solenoid valve?

- The main components of the solenoid valve are?

- Various functions of the solenoid valve:

- Direct acting 2-way solenoid valves / shut-off valves

- Monostable solenoid valves

- Bistable solenoid valves

- 2-way direct acting solenoid valves NC / NO

- 3-way direct acting solenoid valves NC / NO

- Indirect (Servo) controlled solenoid valves NC

- Assisted lift diaphragm

- Scheme of sealing materials

- Schedule Resistance Table

- Brands

What does a solenoid valve do?

Solenoid valves are valves that are operated electromagnetically. The magnet ensures that the valve can be opened or closed. These valves are used to allow, block or divert liquids or gases. Think of opening, stopping, dosing, distributing or mixing media by means of 2 or more ports. There are 4 different types of solenoid valves for the various applications. Direct, indirect, semi-indirect and pressure-controlled.

There are 4 different types of solenoid valves for the various applications:

- Directly controlled

- Indirectly controlled (servo-controlled)

- Semi-indirect controlled

- Pressure controlled

Click on the link for more information about the different types.

What are the benefits of a solenoid valve?

Solenoid valves are ideal for fast, accurate, frequent and safe switching for various media such as: oil, water, hot water, steam and air. They are small, compact, integrated systems and therefore easy to install.

Solenoid valves are ideal for clean media and are more sensitive to contaminated media. Clean media does not contain slurry, stones, pieces, debris that can clog the solenoid valves.

A filter can be a solution for unclean media, but perhaps another valve / valve / ball valve / butterfly valve is better suited for the contaminated medium.

Do you have questions? Call or email us. We are happy to advise you.

Tel: +31(0)499 49 10 90

E-mail: info@aimfluid.nl

How do you select the right solenoid valve?

- What is the medium?

- What is the right material for the body?

- What is the connection size (DN)?

- What is the connection?

- What is the connection type?

- What is the coil voltage?

- What is the seal?

- What is the minimum pressure/working pressure?

- What is the minimum pressure/working pressure?

- What is the function? Monostable, Bistable?

- What is the Kv in m3/h

- What is the temperature of the environment?

- What is the temperature of the medium?

- Is the environment explosion-proof?

Go to our products page here and use the extensive selection menu to find the best solution for your application.

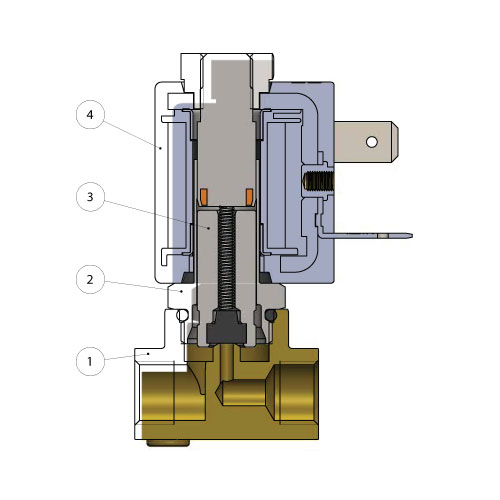

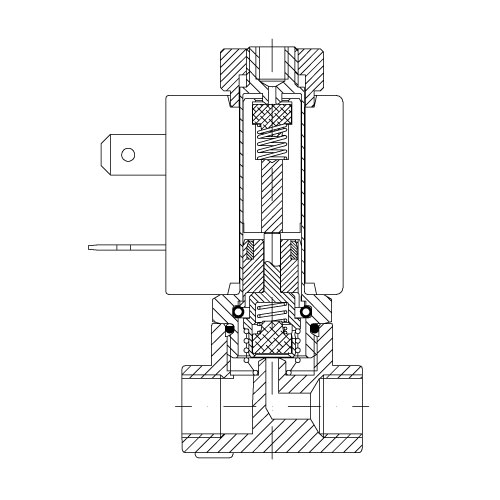

The main components of the solenoid valve are:

The main components of the solenoid valve are:

Solenoid valves are shut-off valves used to switch media under pressure. The action of a solenoid valve is to open or close, directly or indirectly, when the coil is energized.

1. The base housing, which has inlet and outlet connections and an opening for media flow.

2. The core guide tube, with the core, where the coil is mounted.

3. The plunger, which in some cases serves as a seal, that slides into the core guide tube.

4. The coil, which produces the magnetic field required to move the core / plunger.

Stainless Steel

2/2-way indirect acting

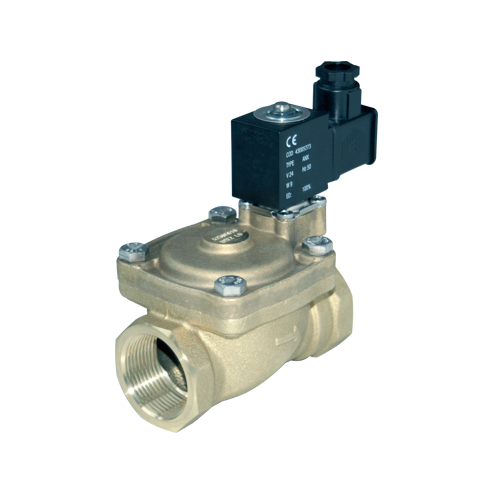

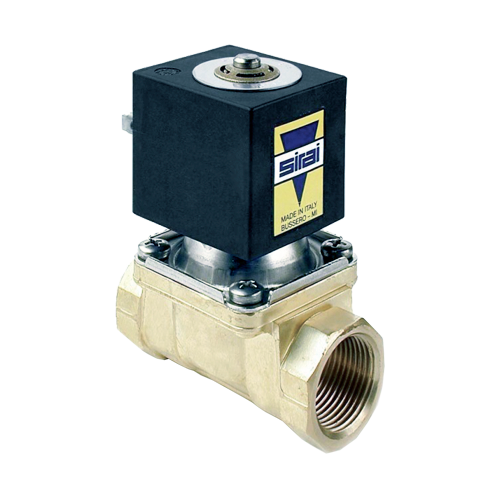

Brass

2/2-way indirect acting

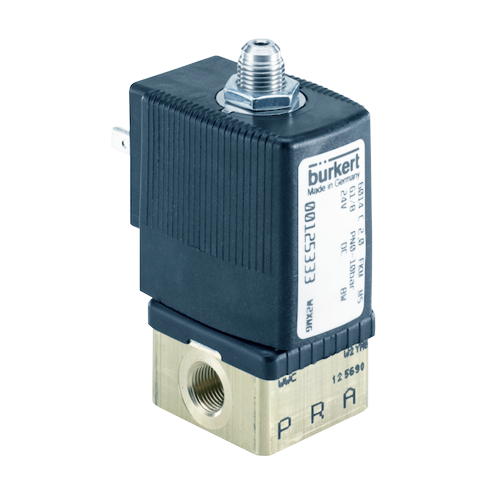

Stainless Steel

2/2-weg direct acting

Brass

2/2-weg direct acting

Stainless Steel

3/2-way direct acting

Brass

3/2-way direct acting

Various functions of the solenoid valve

Direct acting 2-way solenoid valves / shut-off valves

With the direct acting solenoid valve, the clapper seal is attached directly to the solenoid core. In a currentless state a valve (on its seat) is closed and in an electromagnetically energized state it is opened.

2/2 way direct acting solenoid valves for both normally closed (NC) and normally open (NO) versions operate from a differential pressure of 0 bar. A 2/2 way valve has two connections and two switch positions. When the coil is energized, the valve will switch from one switch position to the other switch position.

Monostable solenoid valves

These are solenoid valves where the valve has a preferred position. If the command signal (in this case compressed air) is lost, the valve will return to the preferred position. The valve therefore has 1 stable position.

Bistable solenoid valves

This solenoid valve has no preferred position. If the signal is lost, it will remain in the last switched position until an opposite signal causes the valve to switch back. The valve therefore has 2 stable positions.

2-Way Solenoid Valves (Indirect Acting and Direct Acting)

2/2 solenoid valves (2 connections 2 switching positions) are there to close or open a medium flow.

They are available in two versions:

- 2-way currentless closed / voltageless closed NC, normally Closed

- 2-way de-energized open / de-energized open NO, normally Open

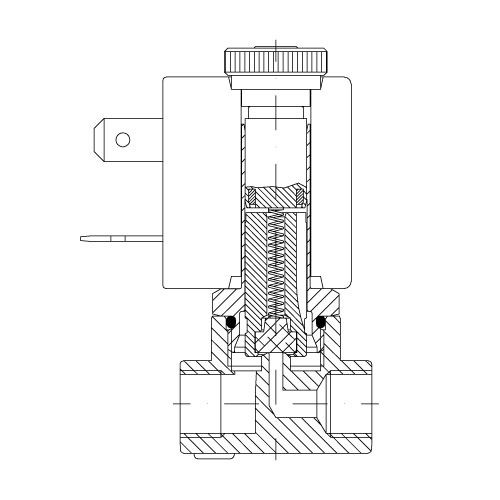

2-way direct acting | Normally closed

2-way direct acting | Normally closed

In a normally closed version (2/2 NC), a 2-way solenoid valve has an inlet and an outlet connection in the valve body / bottom housing.

In this case, the plunger seal prevents the medium from flowing through the opening.

When connected to an electrical supply, the orifice opens allowing the inlet to feed the exhaust port.

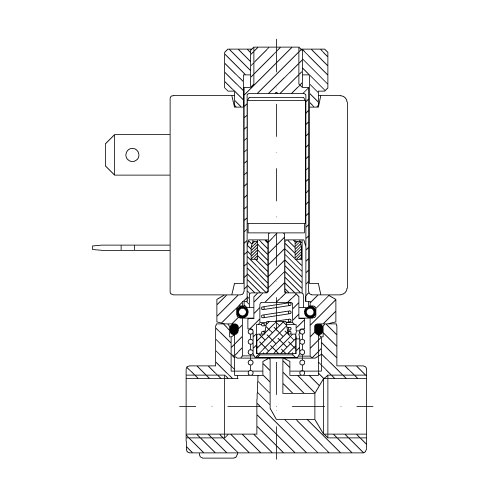

2-way direct acting | Normally open

2-way direct acting | Normally open

In a normally open version (2/2 NO), a 2-way solenoid valve has an inlet and an outlet connection in the valve body / bottom housing.

In this case, the plunger seal removed from the opening is open and the inlet is connected to the outlet.

When connected to an electrical supply, the opening is closed causing the inlet to be disconnected from the outlet port.

Direct acting 3-way solenoid valves / shut-off valves

3/2 solenoid valves (3 connections 2 switching positions) 3-way solenoid valves can be divided into three categories, ie:

- 3-way universal (universally applicable NO or NC)

- 3-way current-free closed / voltage-free closed NC, normally closed

- 3-way open current-free / open voltage-free NO, Normaly Open

3/2 way direct acting solenoid valves for both normally closed (NC) and normally open (NO) versions operate from a differential pressure of 0 bar. A 3/2 way valve has three connections and two switch positions. When the coil is energized, the valve will switch from one switch position to the other switch position.

The 3-way universal solenoid valves are for changing a flow direction medium (distribution) or for mixing two media. They can also be used as a 3-way voltage-free closed or voltage-free open.

The non-universal solenoid valve versions are largely used as a control valve for controlling single-acting actuators.

Special NAMUR control valves are available for single-acting actuators with NAMUR connection.

3-way direct acting | Normally closed

3-way direct acting | Normally closed

In a normally closed version (3/2 NC) the 3-way solenoid valve has an inlet and outlet connection in the body / bottom housing and an outlet connection above the core.

In this case, the plunger seal prevents the medium from flowing through the inlet opening. The inlet and outlet ports are located on each end of the plunger.

When connected to an electrical supply, the exhaust port (vent port) closes and the inlet port is connected to the user port.

3-way direct acting | Normally open

3-way direct acting | Normally open

In a normally open version (3/2 NO) the 3-way solenoid valve has an inlet and outlet connection in the body / bottom housing and an outlet connection above the core.

In this case, the plunger seal has been removed from the inlet port and the outlet port is closed to allow fluid to flow from the inlet port to the user port.

When connected to an electrical supply, the exhaust port (vent port) opens and the connection between the inlet port and the user port is closed.

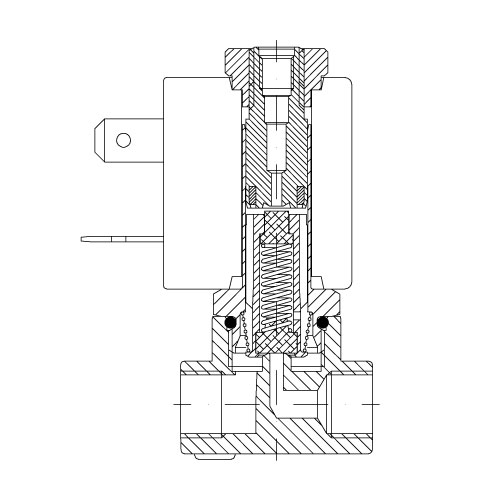

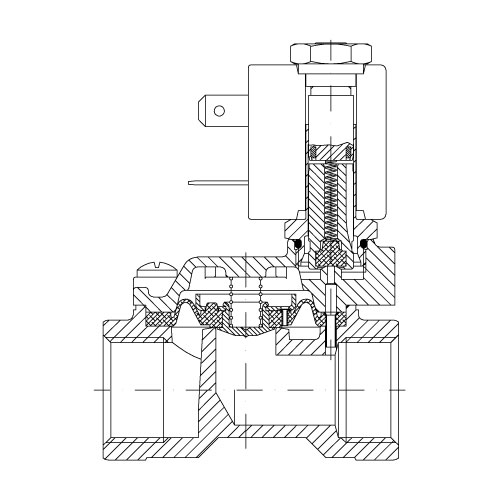

Indirect-acting (Servo-controlled) | Normally closed

Indirect-acting (Servo-controlled) | Normally closed

With larger openings, the static pressure increases and it is still necessary that the magnetic field produced by the coil can control these forces. This is achieved by using servo-controlled action in the solenoid valve.

In this design, the media pressure helps to keep the main valve seal closed.

The normally closed design (2/2 NC) has an inlet and outlet connection in the valve body. When the coil is not energized, current is blocked by the main seal. That can be a diaphragm or a piston design.

In this mode, the medium flows through a small hole in the membrane or

piston and helps to close the valve. When the solenoid is energized, the pilot hole opens, allowing the medium above the main seal to escape and the main valve seal to open.

This type of solenoid valve requires a minimum differential pressure to operate.

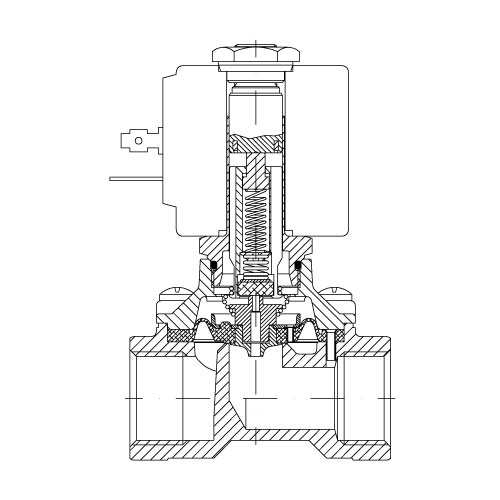

Assisted-Lift diafragma

Assisted-Lift diafragma

They are available with an asisted lift pilot design operated by a diaphragm and normally closed (2/2 NC).

In these models, the plunger is mechanically attached to the diaphragm and controls the center pilot opening and the stroke of the main seal.

This design allows the valve to operate with zero differential pressure.

Sealing materials

An important part of solenoid valves are sealing materials. The most commonly used sealing materials are NBR, EPDM, FPM (Viton) and PTFE (Teflon). The choice of material is largely determined by the dependence on the chemical properties and the temperature of the medium that has to be controlled by the solenoid valve. The right choice is decisive to ensure a long life and optimum performance of the solenoid valve. See table sealing materials for the advantages and disadvantages of the different sealing materials.

Target | Trade name | General characteristics | Typical applications |

NBR (Acrylic-nitrile bu- tadylene) | BUNA -N PERBUNAN ELAPRIM JSR-N | A synthetic elastomer with good mechanical and thermal properties. | Water (max T = + 70 ° C) Air (max T = + 90 ° C) |

EPDM (Ethylene-propyl- ene-dylene ) | BUNA- AP DUTRAL NORDEL | A synthetic elastomer derived from the copolymerization of ethylene and propylene. | Hot water and steam. Detergents. |

FPM (Fluorocarbon) | VITON TECNOFLON FLUOREL | Derived a synthetic elastomer | For general use up to + 140 ° C |

PTFE (Polytetra- fluorethylene) | TEFLON | Uses thermoplastic material also filled with a mineral resin. | For general use up to + 180 ° C |

Resistance table

The following table is intended to give an indication of the general characteristics regarding compatibility with the different materials and media.

To determine the resistance of the materials to corrosive liquids, it is important to know all the data regarding: temperature, concentration and media composition.

Media | Messing | Roestvrij staal | NBR | EPDM | FPM | PTFE |

Acetone | Yes | Yes | No | Yes | No | Yes |

Acetylene | Yes | Yes | No | Yes | Yes | Yes |

Argon Hold | Yes | Yes | No | Yes | Yes | Yes |

Benzol | Yes | Yes | No | No | No | Yes |

Butane | Yes | Yes | No | No | Yes | Yes |

Calcium monoxide | Yes | Yes | Yes | Yes | Yes | Yes |

Carbon dioxide (liquid) | No | Yes | No | No | No | Yes |

Carbon disulphide | Yes | Yes | No | No | No | Yes |

Chloroform | Yes | Yes | No | No | No | Yes |

De-ionised water | No | Yes | Yes | Yes | Yes | Yes |

De mineralised water | No | Yes | Yes | Yes | Yes | Yes |

Dry carbon dioxide (gas) | Yes | Yes | Yes | Yes | Yes | Yes |

Ethane | Yes | Yes | Yes | No | Yes | Yes |

Ethanol | Yes | Yes | No | No | No | Yes |

Ethyl acetate | Yes | Yes | No | No | No | Yes |

Ethyl cloride | Yes | Yes | Yes | Yes | Yes | Yes |

Ethyl glycol | Yes | Yes | Yes | Yes | Yes | Yes |

Formeldehyde | Yes | Yes | Yes | Yes | Yes | Yes |

Freon | Yes | Yes | No | No | No | Yes |

Fuel oil | Yes | Yes | Yes | No | Yes | Yes |

Glycerine | Yes | Yes | Yes | No | Yes | Yes |

Hard water | Yes | Yes | Yes | Yes | Yes | Yes |

Helium | Yes | Yes | Yes | No | Yes | Yes |

Heptane | Yes | Yes | Yes | No | Yes | Yes |

Heaxane | Yes | Yes | Yes | No | Yes | Yes |

Hot water <75°C | Yes | Yes | Yes | Yes | Yes | Yes |

Hot water and steam <140°C | Yes | Yes | No | Yes | No | Yes |

Hydrogen | Yes | Yes | No | No | Yes | Yes |

Hydrogen dioxide | No | Yes | No | No | Yes | Yes |

Isobutane | Yes | Yes | Yes | No | Yes | Yes |

Isopentane | Yes | Yes | Yes | No | Yes | Yes |

Methane | Yes | Yes | Yes | No | Yes | Yes |

Methanol | Yes | Yes | No | Yes | No | Yes |

Methyl cloride | Yes | Yes | No | No | No | Yes |

Mineral oil | Yes | Yes | Yes | No | Yes | Yes |

Natural gas | Yes | Yes | Yes | No | Yes | Yes |

Neon | Yes | Yes | Yes | No | Yes | Yes |

Nitrobenzene | Yes | Yes | No | No | No | No |

Nitrogen | Yes | Yes | Yes | Yes | Yes | Yes |

Oxygen | Yes | Yes | Yes | No | Yes | Yes |

Pentane | Yes | Yes | Yes | Yes | Yes | Yes |

Petrol | Yes | Yes | No | No | Yes | Yes |

Propane-n | Yes | Yes | Yes | No | Yes | Yes |

Soapy water | Yes | Yes | Yes | No | Yes | Yes |

Toluene | Yes | Yes | No | No | Yes | Yes |

Trichlorethylene dry | Yes | Yes | No | No | Yes | Yes |

Vinegar | Yes | Yes | No | Yes | No | Yes |

Water with glycol | Yes | Yes | No | No | Yes | Yes |

Xilol | No | Yes | No | No | Yes | Yes |

Solenoid Valves

aim fluid control has an extensive range of solenoid valves to steer, control and manage your medium (neutral, steam, hot water, aggressive, pneumatics and explosion hazard) in the right direction (s). So many applications, so many solenoid valves. We are happy to help you come to the right technical and price-technical solution.

- 2-weg Magneetventielen (directwerkend)

- 2-weg Magneetventielen (indirectwerkend/servogestuurd)

- 3-weg Magneetventielen (indirectwerkend en directwerkend)

- Assisted-Lift diafragma Magneetventielen

- Magneetventiel RVS

- Magneetventiel Messing

- Magneetventiel Kunststof

- Magneetventiel Aluminum

- Magneetventiel Namur

Contact us now!

The choice for the right solenoid valve is entirely up to you. We will of course be happy to advise you on which solenoid valve is most suitable for your application. Do you want to know more or do you have questions?

Then please contact us. This can be done by calling +31 (0) 499 49 10 90. Feel free to schedule an appointment with us by filling in the contact form.

Ekkersrijt 7310

5692 HH Son en Breugel

+31(0)499 49 10 90

info@aimfluid.nl

Stay informed of news & promotions