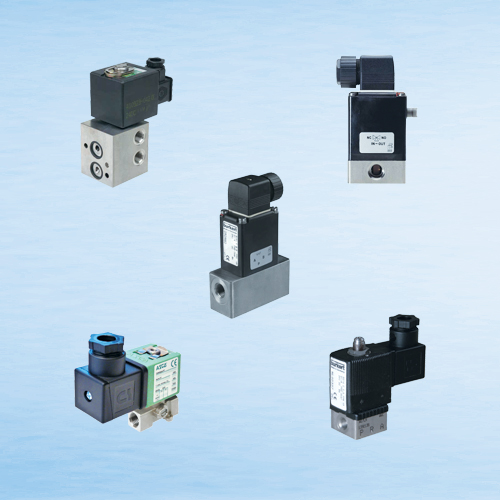

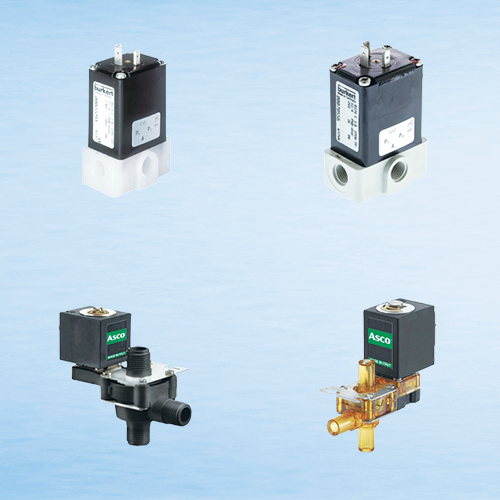

3/2-way solenoid valves direct acting

n direct-acting solenoid valves, the magnet core also functions as the closing device. Two construction principles can be distinguished

1. The valve seal is integrated in the magnet core

2. The valve seal is mechanically connected to the magnet core

Depending on whether or not energized condition of the coil, the bore will be opened automatically or closed.

As a rule, the power of the electromagnet alone must ensure that the disc opens against the flow of the medium.

Supported by the medium pressure, a closing spring above or around the magnetic core must hold the valve closed.

The effect is independent of the line pressure or flow volume, and can be used from 0 bar up to the stated maximum allowable pressure difference.

The maximum allowable differential pressure is by a direct-acting solenoid valves depending on the force of the electromagnet and the size of the passageway.

Embodiments in which the seal is integrated into the magnetic core tend to be small in the passage of 1 to 8 mm of stock to a pressure of 0 to 200 bar

The versions in which the mechanical valve seal is connected to the magnet core are often used for applications with low-pressure and to pass through from 8 to 75 mm.

The valve seals can be of many types of elastomers and plastics are manufactured mostly NBR, EPDM, FKM or PTFE but VMQ, CR, UR, CA or FFKM.

Ekkersrijt 7310

5692 HH Son en Breugel

+31(0)499 49 10 90

info@aimfluid.nl

Stay informed of news & promotions