Rastelli Valves

|

Rastelli Valves

aim fluid control is proud te be partner of Rastelli Valves.

About Rastelli

Rastelli Rubinetterie by your side since 1954

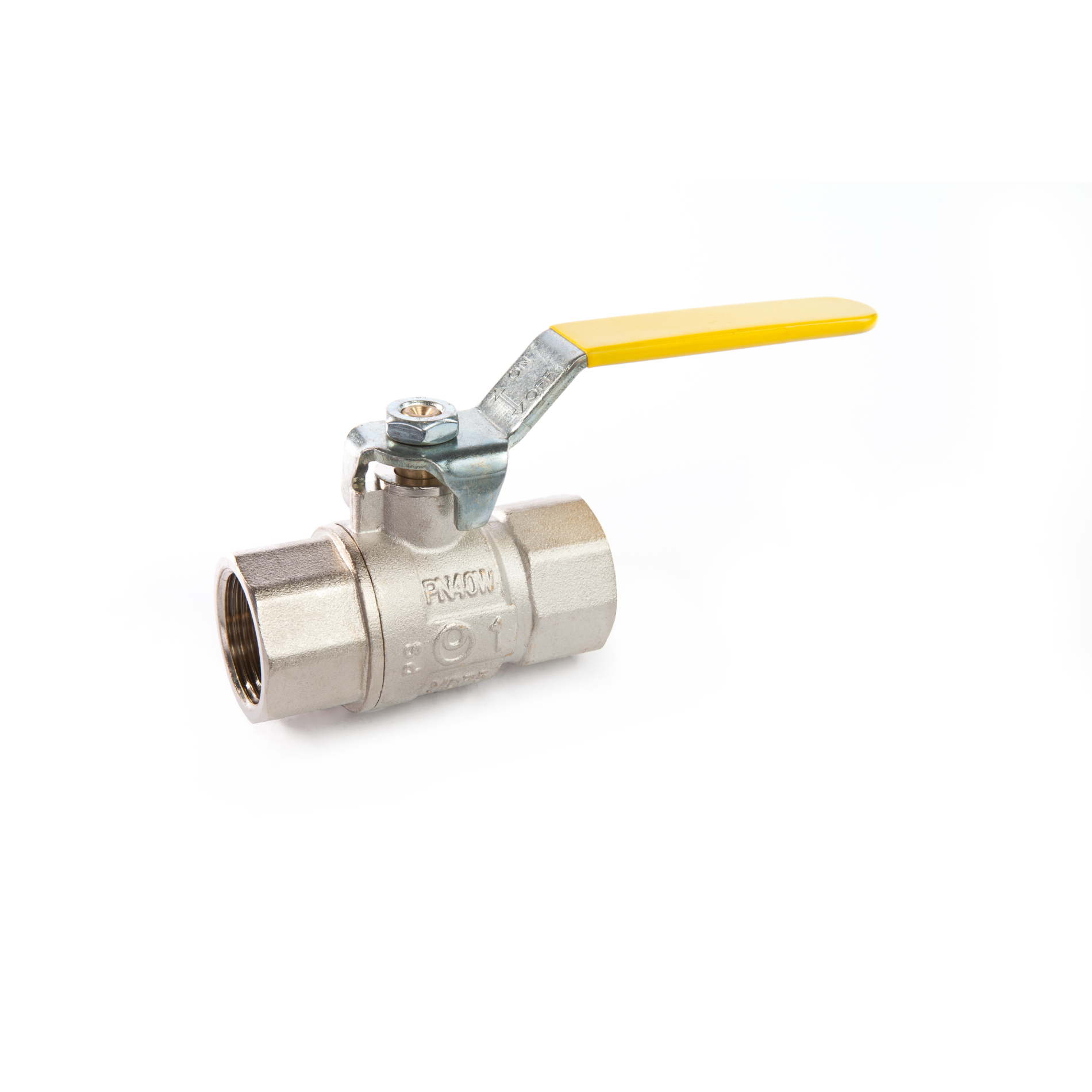

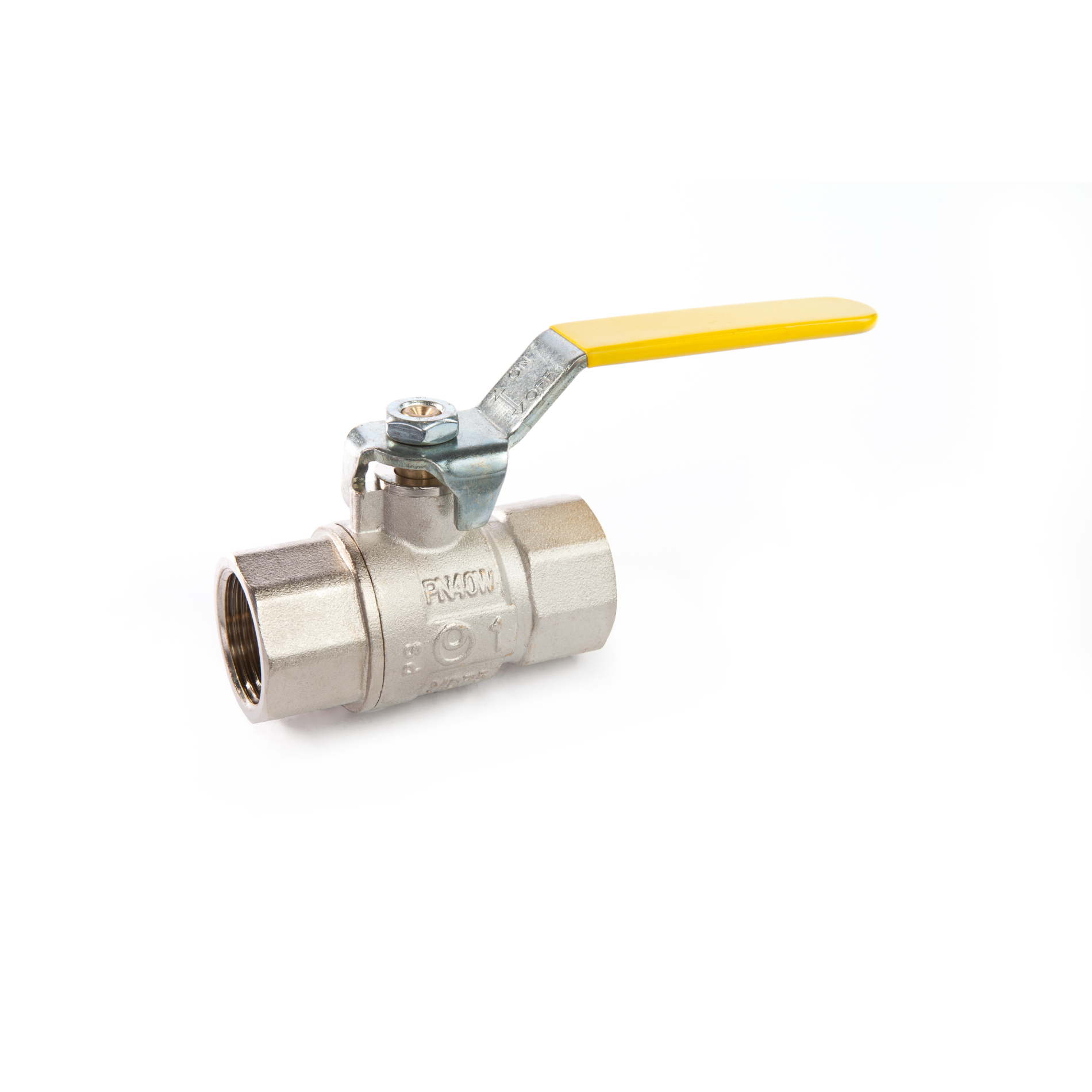

They have been producing valves, brass and bronze components and accessories for the plumbing and heating sector, irrigation and industry for over sixty years; focusing always on the wide range, quality and durability over time of our products.

THE BIRTH

From artisan to industry.

Founded in 1954, Rastelli Rubinetterie quickly became a company in continuous development.

GROWTH

Production grows rapidly in the post-war and reconstruction years. New tooling machines find place in our production departments. The number of employees increased and so did the production capacity.

During the ’70s, Rastelli Rubinetterie starts the production of ball valves.

IMPORTANT CHANGES

New headquarters! It is he beginning of the ’80s. In the new plant in Invorio near Lake Orta, the storage semi-finished material, production, logistics departments as well as the administrative, technical and commercial offices find place.

THE ’90s

The ’90s saw another important change.

A complete wing of the plant is dedicated to the production of “Y” strainers. Rastelli’s strainers are available in different materials – brass and bronze – and in different versions: for this reason even the most specific needs of our customers are met!

In the same years they successfully entered the international markets: about half of Rastelli’s production is exported all around the World.

THE PRODUCTION PROCESS

Selected raw material

The raw materials used in the production of Rastelli’s items are bronze ingots, brass ingots and bars, materials found at the best Italian producers, the analysis certificates are available.

Hot Forging

For the hot forging of brass, Rastelli relies on professionals in the sector in the area, a territory that has always been recognized as the largest producer of valves and taps in Italy. Their experience combined with that of our suppliers allows us to have high quality material.

Bronze & Brass casting

External foundries, always present in the local area, work as a team with Rastelli for the casting of bronze and brass. An ancient art handed down over the years from father to son.

Sandblasting

This process is essential for the cleaning and the preparation of the items for subsequent processing on machine tools and for surface treatments such as nickel and chrome plating.

Acceptance

Before proceeding to assembly, a process that takes place entirely within our factories, the semi-finished products are subjected to a rigorous quality control: once all the incoming tests have been passed, the subsequent production phases can begin.

Quality controls

Their products are finally subjected to the latest tests and quality controls, once this last step has been passed the Rastelli valves are ready to be boxed and to reach you.

Semi-finished & finished products warehouse

The large availability of semi-finished material ready to be assembled, but also the possibility to have stocks of finished products ready for sales, allow Rastelli to be versatile, fast and punctual in shipments, thus satisfying its customers.

Go to webshop Rastelli Valves

Non-return Valves

Technical data downloads

Non-return Valves

Tailor-made solutions

Based on the trinity of People, Customization & Technology, relieving you is the core of what aim fluid control has to offer you. If technology is second nature to us, relieving you might be our first. We call it relieving you because we offer technical, logistical and cost-saving solutions - from idea to solution & implementation - so that the continuity of your flow & fluid process remains guaranteed and / or is improved as well as your peace of mind.

Advice & Deed

From advice on complex issues to the simple ordering of (repeat) orders via our webshop, you can deploy us as a supplier of parts, assembler, product specialist, process specialist, technical adviser, engineer, product developer, project manager or total provider, depending on your needs.

The right technical, logistical and customized solutions

Solving your issues is central at all times. This concerns more than just the focus on applications, processes and products. Our multiple brand policy gives you a wide choice of products and price categories. In combination with our technical know-how and solution-oriented approach, we can deliver customized solutions in many, if not all, cases.

Call or e-mail us!

We will of course be happy to advise you on your technical and logistical support and all your customized work. Do you want to know more or do you have questions?

Then please contact us. This can be done by calling +31(0)499 49 10 90. Feel free to schedule an appointment with us by filling in the contact form.

Ekkersrijt 7310

5692 HH Son en Breugel

+31(0)499 49 10 90

info@aimfluid.nl

Stay informed of news & promotions