Charles Austen Pumps

Air blowers

Charles Austen | Pumps

Air blowers

Air blowers from Charles Austen are designed for use in sewer aeration applications. The range consists of the Enviro air pump for aeration of the waste water in the first phase of the treatment.

Other applications include aeration for koi ponds and spas / whirlpools, rainwater harvesters, basement drains, pool emptying, flood prevention and fuel cell production.

Installation Charles Austen ET Air blowers

Instructies voor het juist installeren en onderhoud van Chareles austen ET Luchtblowers

Installation

Charles Austen ET Airblowers Installation instructions for Koi basins and IBAs

Choice

The choice of the right air blower for the oxygen supply in Koi basins and ibas is often underestimated. To prevent disappointments, it is therefore important to determine (approximately) what the air blower's capacity should be. After all, blowers that are selected too light become too hot, burn through or get stuck due to overload. However, it is also not good to install a (much) too heavy blower for a light application, because that can also cause damage to the pump. Below we list a number of important points for attention for the correct selection and installation of a blower.

Depth

The optimum depths for the blowers are: ET30 and ET40: 1.10 meters (maximum 1.70 meters) ET60 and ET80: 1.50 meters (maximum 1.70 meters) ET100 and ET120: 1.80 meters (maximum 2, 20 meters) These values are based on a full pipe passage from the pump to the aerators (bubbling stones, membranes, etc.). With the ET30 and ET40 this is a 14 mm hose and with the ET60 through ET120 it is 18 mm.v

Choice

The blower must be at least 30 cm away from a building. To prevent overheating due to the sun, the pump must be placed in a shaded area. Do not cover the pump or place it in poorly ventilated areas. Do not put the pump in a place with high wind; prevent dust in the suction. Do not place the pump in the water. Install the blower above the water level. Place the pump horizontally on a flat surface. Do not place the pump in locations where excessive moisture is present. If the pump or plug is damaged when opening the box, contact the dealer where you purchased the pump. Provide a grounded and separate outlet that is only intended for the pump. Electrical work on the pump may only be carried out by a qualified electrician.

Connection

Use a flexible hose or PVC tube at the outlet of the pump that connects to the bubbling stone in the pond or IBA. Make sure there is no kink in it. The hose must be attached with a clamp ring. If taps must be made to several aerators (effervescent stones and the like) via air distributor (s), the pipe to these distributor (s) must not be drastically reduced. Preferably, this line must maintain full passage and only use thinner hose from the manifold.

usage

All circumstances that result in more back pressure (such as the flow to a hose with a smaller diameter, too small ball valves, multiple aerators, contaminated aerators, extremely long pipes), require a part of the pump power and are therefore at the expense of the aforementioned maximum water depths. If the blower is not used according to advice, the pump will become unnecessarily hot due to too high a back pressure. The lifespan is drastically shortened as a result. The best way to constantly check the correct back pressure is to mount a pressure gauge on the outlet of the blower.

Maintenance

Clean the filter (on the top of the blower) every 3 months. Check the pressure and volume with a pressure gauge (available from your dealer). Regularly check the aerators (effervescent stones, membranes, etc.) for contamination and, if necessary, clean or replace them.

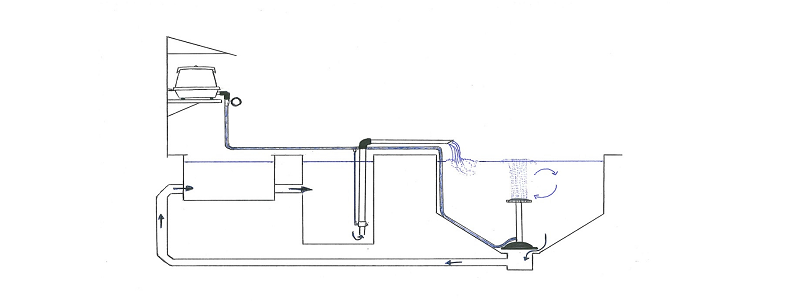

Cross section drawing basin

Tailor-made solutions

Based on the trinity of People, Customization & Technology, relieving you is the core of what aim fluid control has to offer you. If technology is second nature to us, relieving you might be our first. We call it relieving you because we offer technical, logistical and cost-saving solutions - from idea to solution & implementation - so that the continuity of your flow & fluid process remains guaranteed and / or is improved as well as your peace of mind.

Advice & Deed

From advice on complex issues to the simple ordering of (repeat) orders via our webshop, you can deploy us as a supplier of parts, assembler, product specialist, process specialist, technical adviser, engineer, product developer, project manager or total provider, depending on your needs.

The right technical, logistical and customized solutions

Solving your issues is central at all times. This concerns more than just the focus on applications, processes and products. Our multiple brand policy gives you a wide choice of products and price categories. In combination with our technical know-how and solution-oriented approach, we can deliver customized solutions in many, if not all, cases.

Call or e-mail us!

We will of course be happy to advise you on your technical and logistical support and all your customized work. Do you want to know more or do you have questions?

Then please contact us. This can be done by calling +31(0)499 49 10 90. Feel free to schedule an appointment with us by filling in the contact form.

Ekkersrijt 7310

5692 HH Son en Breugel

+31(0)499 49 10 90

info@aimfluid.nl

Stay informed of news & promotions